Custom Notebook Specs That Reduce Unit Cost Without Killing Quality

Introduction

Balancing price and quality is a constant challenge in the notebook industry. Buyers sourcing for retail chains, promotional campaigns, or corporate clients often want the best quality at the lowest possible cost. However, cutting corners can backfire, resulting in dissatisfied customers or rejected shipments. The key is to optimize custom notebook specifications strategically—reducing unit costs while preserving the performance and appearance buyers expect.

Paper Choices: GSM and Ruling

Paper accounts for a significant portion of notebook cost. By carefully selecting GSM (grams per square meter), buyers can lower expenses without sacrificing usability. For example, using 80 GSM instead of 100 GSM paper is often sufficient for standard writing notebooks, as long as it remains bleed-resistant. Similarly, single-line ruling is less expensive to print than complex graph or dotted patterns, making it a practical choice for mass-market items.

Working with an experienced Custom Notebook Supplier allows buyers to review paper samples and identify the right balance between quality and price.

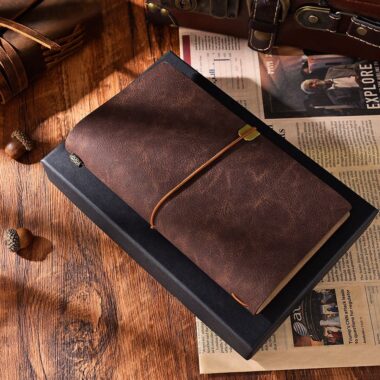

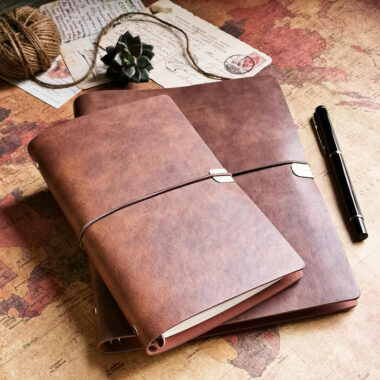

Cover Materials: Affordable but Durable Options

Cover material is another cost driver. Genuine leather or premium PU significantly increases the price per unit, while alternatives such as coated paperboard, kraft, or fabric laminates can still deliver an attractive look at a fraction of the cost. For corporate giveaways, PU or textile finishes provide a premium feel without the expense of genuine leather.

Retailers stocking school or office supplies often prefer flexible softcovers, which reduce production costs and improve portability.

Binding and Finishing Adjustments

Binding style directly impacts production cost.

-

Staple binding is the most economical for thin notebooks.

-

Perfect binding offers a professional look for mid-range products.

-

Spiral or wire-o binding adds convenience but can increase costs slightly.

By selecting the right binding for the target audience, companies can save money while ensuring usability. A reliable Notebook Supplier can advise which binding styles align with specific market demands.

Accessories: Keep It Simple

Elastic bands, pen loops, and pockets add value but also raise costs. Buyers should evaluate whether these accessories truly enhance usability for their target customers. For high-volume retail orders, removing unnecessary add-ons can significantly reduce costs. For corporate clients, including just one key accessory—such as a branded elastic band—may be enough to elevate brand perception without overspending.

Packaging Considerations

Custom packaging such as rigid gift boxes or shrink-wrapped sets can push up unit costs. Opting for simple yet protective carton packaging reduces expenses, especially for wholesale orders. Eco-friendly kraft sleeves are another cost-efficient option that simultaneously reinforces sustainability messaging.

Striking the Right Balance

The secret to reducing costs lies not in cutting quality but in designing specs with precision. Instead of selecting the most expensive materials, buyers should prioritize features that directly impact the end-user experience—paper smoothness, binding strength, and cover durability. Secondary elements like packaging or add-ons can be adjusted to control budgets.

Conclusion

Custom notebooks don’t have to be expensive to look professional and perform well. By making smart adjustments to paper GSM, cover materials, binding methods, and accessories, buyers can reduce unit costs while keeping customer satisfaction intact. Partnering with an experienced Custom Notebook Supplier ensures access to a wide range of material and production options, while working with a general Notebook Supplier guarantees consistent quality for bulk orders.