Color Control in Notebook Covers: Pantone, Lab Delta E, and QC

Introduction

For buyers sourcing notebooks in bulk, consistency in cover color is just as important as paper quality or binding. Whether producing branded corporate notebooks or retail stationery collections, even slight deviations in shade can lead to costly rejections. This is where color control tools like Pantone standards, Delta E measurement, and quality control (QC) processes play a critical role.

Pantone Matching: The Global Standard

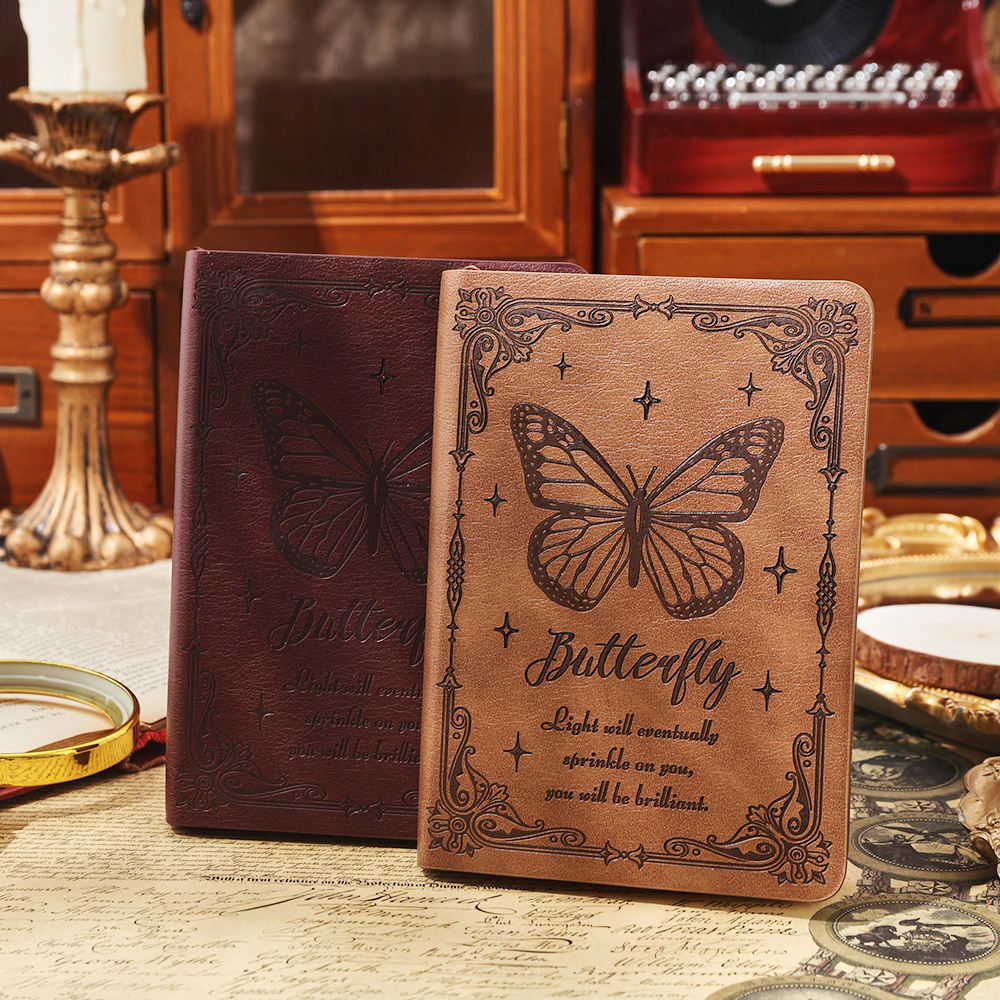

Pantone is the most widely used color reference system in printing and manufacturing. By specifying a Pantone code, buyers ensure that suppliers understand the exact shade required. For notebook covers, Pantone references are especially valuable when brand identity relies on consistent corporate colors.

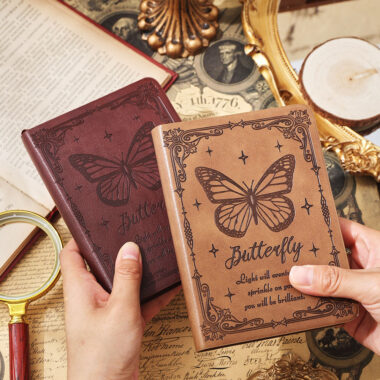

Retail buyers often demand Pantone-matched notebooks to maintain uniformity across entire product lines. Corporate clients also rely on Pantone accuracy to safeguard brand recognition in their promotional materials. Reliable production begins with a qualified Notebook Supplier that can demonstrate accurate Pantone reproduction across different materials, from paperboard to PU leather.

Delta E: Quantifying Color Differences

While Pantone provides the target shade, Delta E (ΔE) measures how close a produced color is to that target. In QC terms, a lower Delta E indicates better accuracy. For most notebook projects, a Delta E of less than 2 is considered acceptable, meaning the human eye cannot easily perceive a difference.

Delta E measurements are crucial for corporate orders where thousands of units must look identical. For example, luxury products sourced through a Leather Notebook Supplier often require tighter Delta E tolerances to meet premium standards.

Quality Control Practices in Color Management

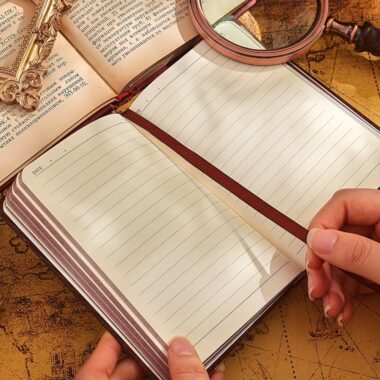

Ensuring accurate and consistent notebook cover colors requires a multi-step QC process:

-

Sample Approval: Buyers approve Pantone-referenced pre-production samples before mass production.

-

Spectrophotometer Testing: Objective color measurements are taken against Pantone values.

-

Batch Comparison: Different production batches are checked for uniformity to avoid mismatched stock.

-

Material Variation Checks: PU, leather, and coated paper may absorb inks differently, requiring adjustments in printing or finishing.

These steps minimize the risk of rework or rejected shipments, saving both buyers and suppliers time and cost.

Market Impact of Color Accuracy

-

Retail: Color consistency enhances shelf presentation and builds consumer trust.

-

Corporate: Precise branding colors maintain a company’s professional image.

-

Promotional Products: Accurate reproduction ensures giveaways reinforce brand identity instead of diluting it.

Conclusion

Color control is not just a technical detail—it’s a business safeguard. By combining Pantone standards, Delta E measurements, and rigorous QC practices, buyers can secure consistency across notebook cover production. Partnering with an experienced Notebook Supplier ensures accurate Pantone matching, while a specialized Leather Notebook Supplier provides premium solutions with strict Delta E tolerances. Together, these suppliers help buyers maintain both brand integrity and customer satisfaction in competitive markets.